Shein’s LATR is the new TPS (Lean, Kanban)

What is the relationship between the fashion world and the automotive industry? Not too much at first glance. But if we dig into the processes, we can find an interesting analogy.

Free link to this article: https://pgillich.medium.com/sheins-latr-is-the-new-tps-lean-kanban-2d3295700860?source=friends_link&sk=297de009e496fc569ce7ad99dd6eac01

Shein is an online fast fashion retailer, which uses Large-scale Automated Test and Re-order (LATR) system to order and deliver products very fast.

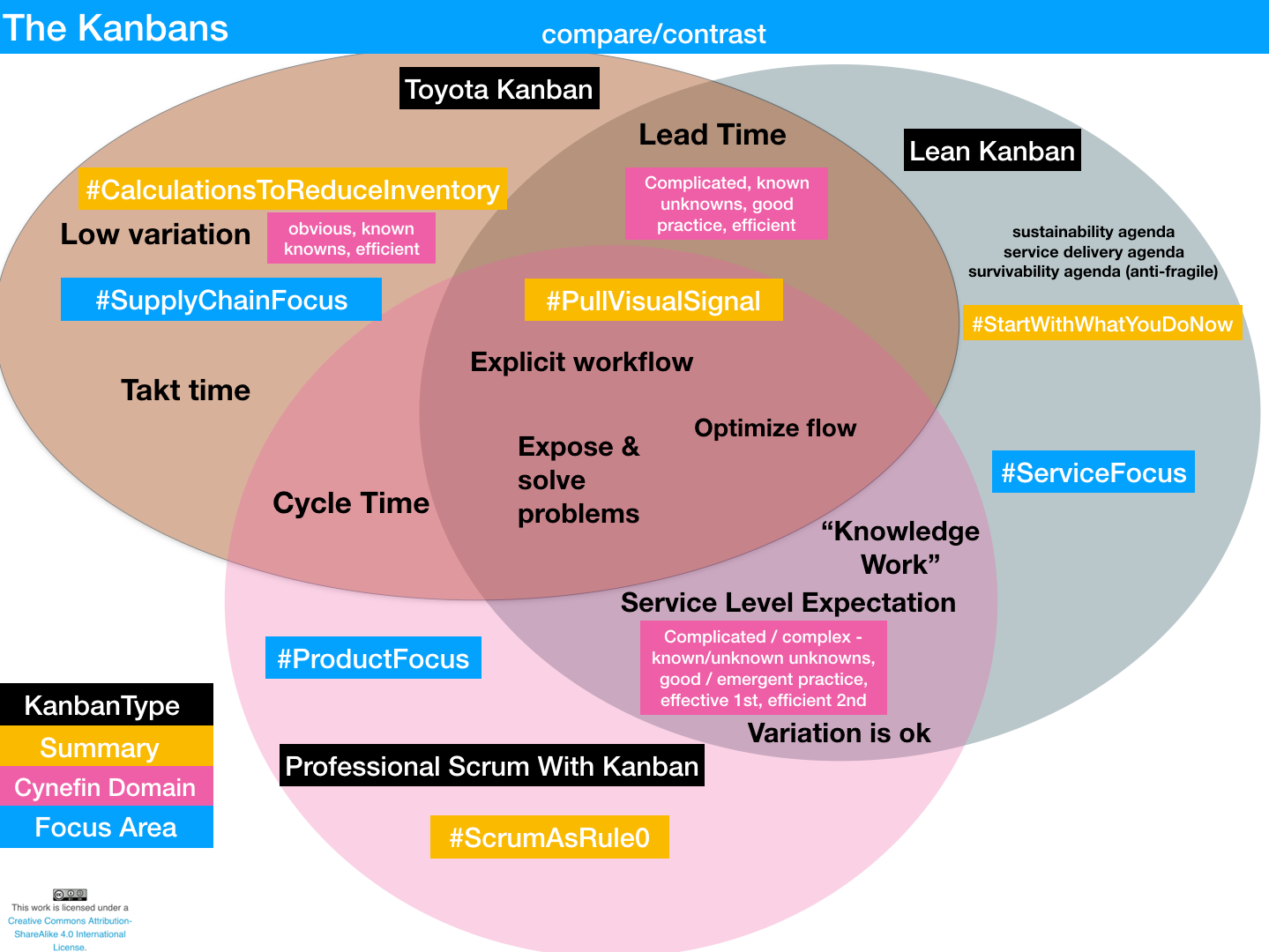

TPS stands for the Toyota Production System, developed by Toyota in order to optimize car manufacturing. It’s the precursor of Lean. Kanban is a TPS methodology for tracking the orders and parts during the manufacturing process. Kanban is adopted as an Agile software development framework, mostly for troubleshooting.

Shein churns out more than average 7000 new models per day, which is much more than the competitors can do. Nevertheless, The typical time from design to production is 1 week, instead of weeks or months. The result of this properties is shorter age of stock:

There are several factors of Shein success, this article focuses on only one factor: how Shein can more and faster churn out new models than its competitors.

Shein uses a highly-optimized ultra-fast fashion model, called LATR. Its key strengths relied on a strong online presence, primarily driven by mobile e-commerce. The loop between users’ feedback about fashion trends, manufacturing is short and fast.

Shein close proximity and strong relationship with its small-to-mid-sized factories that pick up orders daily allow for small units to be placed. They have to use Shein’s supply chain management (SCM) software, in order to Shein track everything. Many argue that Shein behaves more like a food delivery company than a fashion company. Instead of ghost kitchens, Shein utilizes ghost factories.

Shein cuts out any of the remaining middlemen, and has built an advanced cross-border version of the Consumer to Manufacturer (C2M) model. It plugs directly into competitors’ websites and Google Trend Finder to understand what’s in-fashion, designs quickly, and links in-app and on-site user behavior to the backend to automatically forecast demand and adjust inventory in real-time.

Everything is optimized with big data. Each of Shein’s suppliers gets their own account on the platform, which spits out information about what styles are selling well and can also quickly identify which might become future hits. Shein can see the current sales, and then it will tell you to stock up more if you sell well and what you need to do if you don’t sell well. Thankfully the loopbacked process, Shein can optimize fast its managed producing capacity to the best model portfolio.

Whereas Zara typically asks manufacturers to turn around minimum orders of 2,000 items in 30 days, Shein asks for as few as 100 products in as little as 10 days. Depending on the trends of received orders, Shein decides to continue the production or stop it and turn to another model.

So, Shein created a model which continuously optimizes the production line based on big data. Toyota made something similar more than 50 years ago but on pieces of paper. The original name of TPS describes its concept: just-in-time production (JIT), which uses a pull system to eliminate overproduction and continuous improvement (Kaizen) to make the system better and better. TPS uses several loops: a part of loops are used for continuous improvement of the system, another loops are used to drive and track the production. The production is driven by the received new car order, which is divided, distributed and tracked to the part suppliers by Kanban cards.

The whole process was tracked on a Kanban board, which is a good way to discover any production problems.

The arrival time of the parts to the assembly factory is scheduled to the time when it will be built into the car, not earlier. The part suppliers must also adopt this system and loops in order to fulfill Toyota’s requirements.

The feedback and tracking loops ensure Toyota produces only the required cars as fast as possible. At the time, when Toyota worked out TPS, the American car factories remained at the stage of what was worked out by Henry Ford: optimized assembly line, no more. For example, when Chrysler declared bankruptcy in middle of ’70s, Lee Iacocca was shocked when he saw thousands of unsalable Chrysler cars, because the production was not driven by the new car orders.

Toyota’s system was success, so it was adopted to another industry (Lean). In software development, Kaizen was adopted as a continuous improvement methodology (PDCA) and Kanban was adopted as an Agile methodology.

Shein reformed the fast fashion market using modern data handling (big data), focusing on the efficient and short production. The key factor is not secret: continuous improvement with clean and evident goals, combined with inventing and integrating new solutions.

The Western fashion companies are in similar trouble to American car manufacturers more than 50 years ago. Currently the Shein is the leader, but it will be changed if the dropping behind companies can learn from the leader. Other competitors will be sunk.

Toyota had a similar effect in car manufacturing decades ago and changed other industries, too. China is the new Japan. There are worldwide online platforms from China which are better than Western world can do. It’s time to learn from China.

References:

- https://amp-theguardian-com.cdn.ampproject.org/c/s/amp.theguardian.com/fashion/2021/dec/21/how-shein-beat-amazon-at-its-own-game-and-reinvented-fast-fashion

- https://restofworld.org/2021/how-shein-beat-amazon-and-reinvented-fast-fashion/

- https://fourweekmba.com/shein-business-model/

- https://blog.edited.com/blog/shein-business-model

- https://www.lipstickalley.com/threads/shein-the-tiktok-of-ecommerce.4549580/

- https://en.wikipedia.org/wiki/Toyota_Production_System

- https://en.wikipedia.org/wiki/Kanban

- https://nimblebydesign.com/index.php/tag/continuous-integration/

- https://en.wikipedia.org/wiki/Iacocca:_An_Autobiography